- Client Industries

- Aerospace

- Automobile

- Electronics

- Mechanical

- Medical and Dental instruments

- Military And Defence

- Hunting and Fishing

- Products Materals

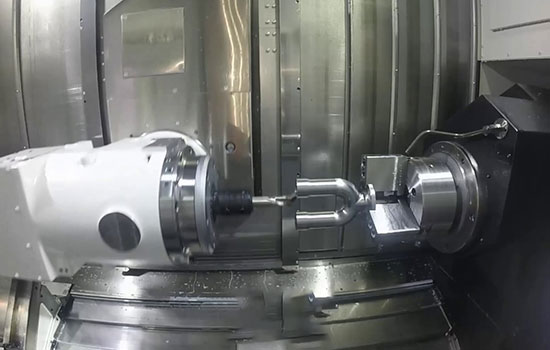

- CNC Turned Parts

- Client Application

- Applications

CNC Turning Parts for Medical Tooling & Medical Mold - Precision Tooling & Mold Components for Medical Equipment Industry

Medical tooling and technology provide high-quality service for the medical and dental instrument industry. Medical tools and molds manufacturing, installment, and use need lots of precision machined CNC Turning Parts. Actually, the CNC medical parts play a significant role in the medical equipment industry, to help medical equipment fabrication and operation to process smoothly.

Dajin Precision Hardware Co., Ltd offers China CNC medical product CNC machining medical tooling parts and medical mold components, striving to be faster and more efficient throughout the manufacturing process, improving machining process, working on realizing the technological advances in machines or lathes, and finding more reliable materials.

We conform to the industry standard and continue to raise the bar on performance for CNC lathe tooling medical components, stock core medical precision parts like the most sophisticated core pins, blanks, and other medical/pharmaceutical tools and components.

Specifications of Our CNC Medical Tooling & Mold Parts

Benefits of Our CNC Medical Tooling & Mold Parts

- Order full traceability.

- Favorable price.

- ISO9001:2015 Certification.

- Cost-effective and efficient machining process.

- One-stop shopping, start from with CNC lathe part CAD/CAM/CAE drawing and requirements through to production, packaging and delivery.

- Our CNC turned and milled healthcare components are subject to our rigorous inspection before shipment.

- Our skilled team has the ability to machine from hard copy drawings, 2D and 3D electronic files.

- Any components delivered under our brand will be ensured to meet your exact specification.