- Client Industries

- Aerospace

- Automobile

- Electronics

- Mechanical

- Medical and Dental instruments

- Military And Defence

- Hunting and Fishing

- Products Materals

- CNC Turned Parts

- Client Application

- Applications

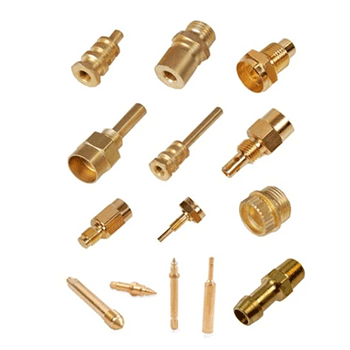

CNC Precision Machining Parts Contact Terminal & Conductive Pins

The CNC contact terminal/pin is an important part of CNC electronic components, passing through the aperture and an interior of the enclosure to emerge from the enclosure at a point opposite the major surface, generally used for testing, conducting, connecting wires and metals, the electrically conductive pins functioning both as a heat sink mount for the case and a case ground pin for the substrate, which are widely used in a wide range of industries including engine bearings, automotive parts, general industrial machinery, mechanical parts, electric appliances, and more.

Dajin Precision is a manufacturer of custom electrically conductive pins and terminal for CNC electronic products with well-equipped testing facilities and strong technical force. We are one of the world's premier suppliers of top-grade precision CNC machining contact terminal, CNC lathe conductive terminal, metal contact pins especially the brass contact pin for different types of equipment in the electronics manufacturing industry.

Our conductive pins CNC turning service are available in different sizes, shapes, ferrous & non-ferrous materials with plain & plated finishes. Capabilities include measuring & testing, single spindle & multi-spindle screw machining, inspection, prototyping, short & large production runs, electrical discharge machining (EDM), assembly, vertical milling, CNC machining, gas & electric welding, deburring, sawing, grinding & centerless grinding, polishing, descaling, degreasing, cold heading, heat-treating, tumbling, thread locking, passivation, plating & rack & barrel plating. Our CNC electronic parts machining service for conductive parts can meet different requirements of customers'.

CNC Machined Conductive Pins Specifications: