What are the Differences Between Brass, Bronze and Copper | Dajin Precision

Brass, bronze and copper are collectively referred to as red metals because of the distinctive reddish color, but the actual color of each metal is not the same. The composition is one of the most reliable methods to differentiate brass and bronze, while it’s not visually and not easy to tell. How to identify brass and bronze? What’s the difference between brass and copper? We need to compare them in many aspects.

What is Brass and Brass Uses

Brass is an alloy that mainly consists of copper, with as much as 40% zinc and other elements (iron, aluminum, silicon, and manganese) added. The varying amount of zinc and other metals will influence the properties, machinability, and color of the alloy. For example, increased zinc will improve strength and ductility. Brass color is available in yellow/gold and ages to light brown. The main types of brass including red brass, yellow brass, 330 brass, 360 brass, and 464 brass. Tin Brass is a typical brass alloy. Brass is commonly used for decorative purposes, musical instruments, nuts, rivets, hinges, and locks.

Properties of Brass

- Low melting point (900 degrees Celsius)

- The density of around 8.73 g/cm3

- High corrosion resistance

- Non-ferromagnetic

- Higher malleability than zinc or copper

- Easy to cast in molds

- Susceptible to stress cracking when exposed to ammonia

- Not as hard as steel

What is Bronze and Bronze Applications

Bronze is an alloy that primarily composed of copper, added 12% tin and small amounts of iron, arsenic, phosphorus, aluminum, manganese, and silicon. Bronze usually starts reddish or brown and ages to dark brown. The main bronze alloys including phosphor bronze, aluminum bronze, silicon bronze, nickel brass, and copper-nickel. The applications of bronze involve the construction of sculptures, musical instruments, and medals, there is a bearing bronze with low friction and high wear resistance is the best choice as bearings, in addition, bronze can also be made into CNC turned bushings, as well as applied in nautical industries and electrical connectors.

Properties of Bronze

- The melting point of 950 degrees Celsius

- The relative density of around 8.8 g/cm3

- Hard and brittle

- High resistance to corrosion from saltwater

- Low friction

- Metal fatigue more than steel

- Good conductor of heat and electricity

What is Copper and What is Copper Used for?

Copper is a soft, malleable, and ductile metal with a minimum of 99.3% copper content, it has very high thermal and electrical conductivity and comes in a pinkish-orange color when the pure copper freshly exposed, then turn to green lastly. Copper is often made into pipes, tubes and fitting for them, or used for bus bars, wire connectors for electrical applications, tools or adornments, and even sterilize wounds and purify drinking water.

Properties of Copper

- Excellent electrical and thermal conductivity

- High strength and formability

- Corrosion resistance

- Can be readily soldered and brazed, as well as welded through gas, arc, and resistance

- Easy to polish and buff to achieve desired texture and luster

- Outstanding ability to fight bacteria

How to Identify/Differentiate Brass and Bronze?

- Scratch the metal with a file, if it can be cut easily, the metal is brass, otherwise, it’s bronze.

- Heat the metal, the one melted faster is brass

- Check out the surface, brass is smooth and lustrous, while bronze is porous and dark.

Price Difference Between Copper, Bronze, and Brass

Generally, copper is more expensive than brass and copper, between the remaining two, bronze prices usually the higher one. But the prices of different grades of the same metal will also be different and will be affected by lots of factors.

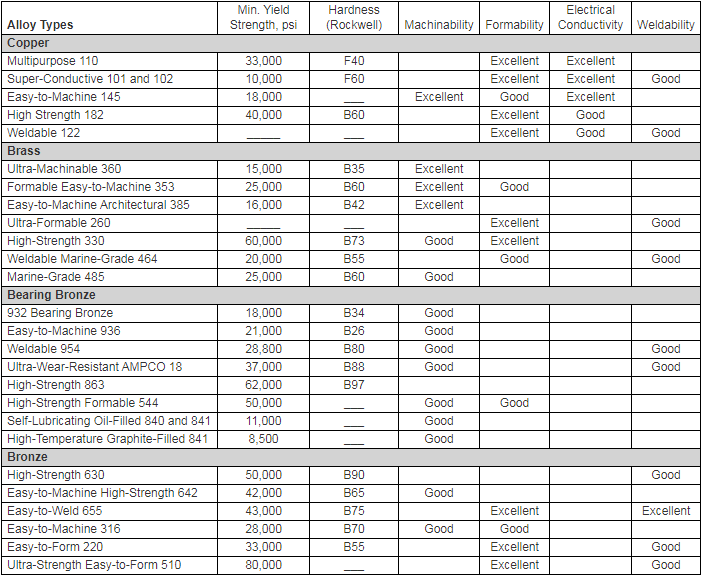

Comparison of Brass, Bronze and Copper Alloy - Difference Between Brass, Bronze and Copper

The direct data of properties and characteristics of these metals can fast show the difference between brass and bronze, copper. The comparison includes popular types and grades of copper, brass and bronze.